X-Ray Inspection

How is X-Ray Inspection used in electronics manufacturing?

Like a doctor or dentist uses X-ray imaging to see through you, we use X-ray imaging to…

Look inside a sealed housing to ensure proper assembly

Look under soldered parts to ensure sufficient solder is in place to remove heat from the part during operation

Inspect PCB solder joints including barrel fills on through vias

The uses are many but the purpose is the same…did the process go as expected?

While most PCB Assemblies and Final Products will not require X-ray inspection…

when you need it we have it.

X-Ray Inspection Case Study

Using X-Ray Inspection on Sealed Sensors

This is an IR occupancy sensor used in high moisture environments.

This image shows a sealed completed assembly. This product requires a pressure test to ensure proper seal. The part is about the size of a fist.

This image shows the occupancy sensor in the X-ray machine.

X-ray allows Fleetwood Electronics to inspect, for proper assembly or possible failures, without need for disassembly or destroying the final product.

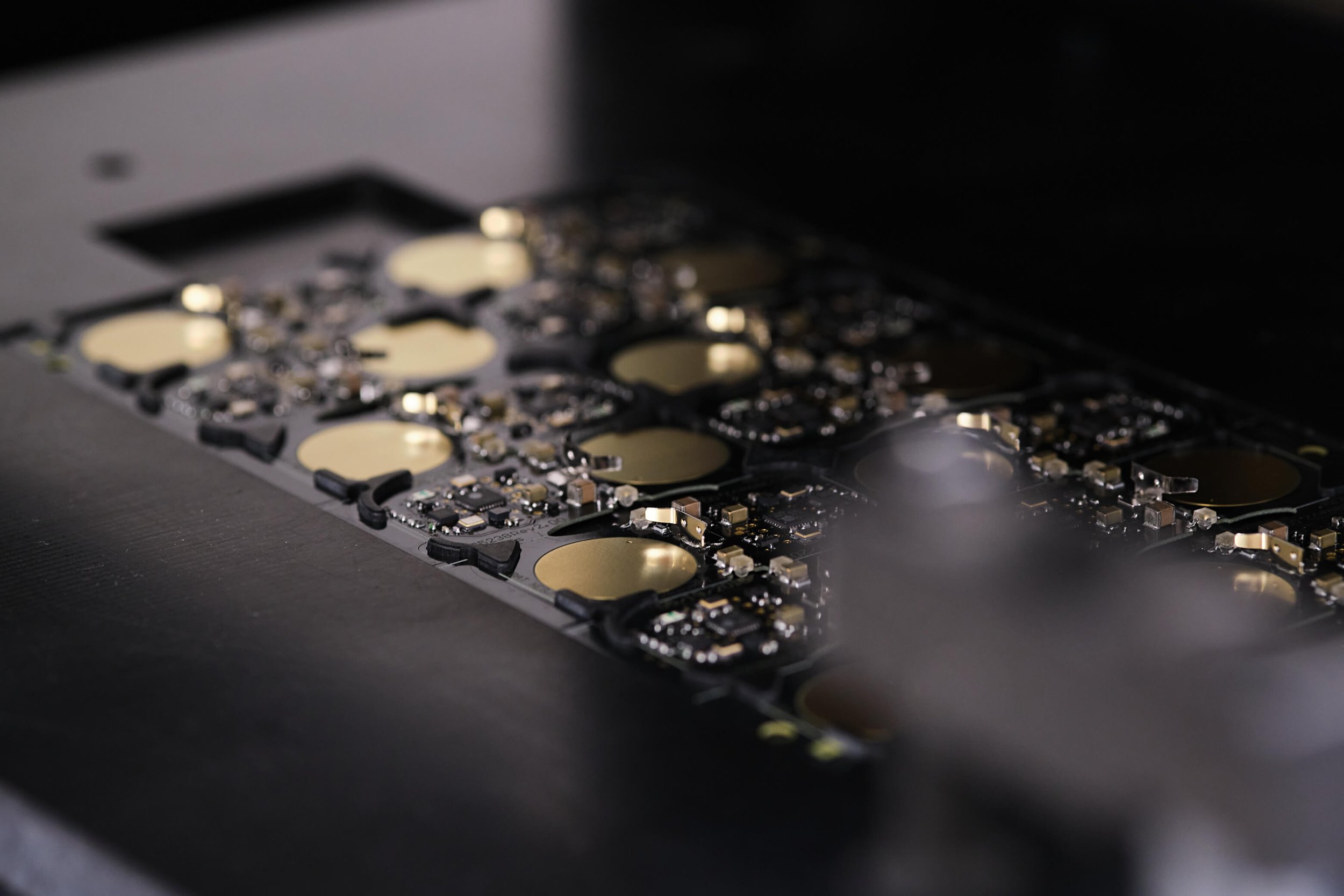

This image shows the inside of the final assembly, zoomed into a specific area on the PCBA.

Solder joints, PCB traces, components and the insides of some components can be seen.

Have a similar need?

Complete the form or contact us directly to start a conversation.

Email: sales@fleetwoodelectronics.com

Phone: 616-820-8202